How to Prevent and Troubleshoot Common Problems in Industrial Stainless Steel Piping Systems

Table of Contents

Stainless steel piping systems are essential across various industries due to their exceptional corrosion resistance, durability, and hygienic properties. However, they’re susceptible to problems during installation, welding, and over time, including corrosion, leaks, contamination, and even cracking from extreme temperatures or pressures. These issues can lead to costly downtime, inefficiency, and safety risks.

This guide is for engineers, technicians, installers, and maintenance professionals. It addresses common challenges, from initial inspection to long-term maintenance, emphasizing best practices and robust quality control to minimize problems, extend system life, and ensure safe, reliable operation.

Understanding Stainless Steel Piping Systems

Before diving into the problems, it’s essential to appreciate the material itself. Stainless steel is an iron alloy containing a minimum of 10.5 percent chromium. This chromium reacts with oxygen to form a thin, protective passive layer that gives stainless steel its corrosion resistance. Different grades of stainless steel (like 304 and 316) offer varying resistance levels depending on their composition, including elements like nickel, molybdenum, and titanium.

While this passive layer is robust, it can be damaged or compromised by mechanical means, chemical exposure, or high temperatures, making the steel vulnerable. This is where many of the problems we discuss originate.

Key Challenges in Stainless Steel Piping

Industrial piping issues are diverse and can manifest at different stages. We will focus on the most prevalent problems:

- Installation Problems: Errors made during the initial setup.

- Welding Problems: Defects introduced during the joining process.

- Corrosion Causes: Degradation of the metal due to environmental interaction.

- Support Problems: Issues related to how the pipe is held and restrained.

- Leaks: Unintended escape of process fluid.

- Contamination: Introduction of foreign materials that compromise performance or purity.

- Overall Failure Prevention: Strategies to ensure system longevity.

- Quality Control & Inspection: Verifying the integrity of the system.

Let’s explore how to prevent and address these challenges systematically.

Guide to Preventing and Addressing Problems

Effective management of stainless steel piping systems requires a proactive approach, starting long before the first pipe is laid. This guide breaks down the process into key steps covering the entire lifecycle.

Pre-Installation Planning and Material Selection

The foundation of a problem-free stainless steel pipe installation begins with meticulous planning and selecting the right materials for the specific application. This is your first line of defense against many potential issues, including pipe corrosion and future pipe leaks.

- Choosing the Right Grade: Not all stainless steels are created equal.

- Consider the process fluid: Is it corrosive? What chemicals are present (especially chlorides)? What is the temperature?

- Consider the environment: Is the surrounding atmosphere corrosive (e.g., coastal, chemical fumes)?

- Consider pressure and temperature requirements: Ensure the chosen grade and schedule handle the operational envelope.

- System Design Considerations: Beyond material, the design impacts system health.

- Handling and Storage: Preventing damage and contamination before installation.

Proper Installation Techniques

Common stainless steel pipe installation problems stem directly from poor workmanship or incorrect techniques. Addressing these during installation is crucial for system integrity and preventing stainless steel pipe leaks.

- Pipe Cutting and Preparation: To avoid cross-contamination from tools previously used on carbon steel, use dedicated tools for cutting stainless steel. Abrasive cutting wheels should be low-chloride and specified for stainless steel.

- Pipe Fitting Installation is a common source of problems. Use the correct fittings for the pipe schedule and application (welded, flanged, mechanical). For mechanical fittings, follow the manufacturer’s specific instructions precisely.

- Flange Connections are critical for system sealing. Use the correct gasket material compatible with the process fluid, temperature, and pressure. Ensure flange faces are clean, smooth, and free from damage.

Throughout the installation process, maintain cleanliness. Tools, pipes, and fittings should be kept clean and free of debris or foreign materials.

Mastering Stainless Steel Pipe Welding

Welding is often used to join stainless steel pipes, and it’s a critical step where many industrial stainless steel piping issues can originate. Proper technique prevents welding defects and maintains the material’s corrosion resistance.

Common Welding Problems:

- Porosity: Gas pockets trapped in the weld metal.

- Cracking: Can occur in the weld metal or heat-affected zone (HAZ) due to shrinkage stress, hydrogen embrittlement, or incorrect material composition.

- Distortion: Warping or deformation caused by uneven heating and cooling.

- Lack of Fusion/Penetration: The weld metal doesn’t properly fuse with the base material, creating weak points.

Preventing Welding Defects

Use qualified welders experienced in stainless steel welding (GTAW/TIG is standard for process piping for its precision and clean welds).

Shielding Gas

Use high-purity inert gas (like Argon) for shielding the arc and molten weld pool to prevent oxidation and porosity.

Back Purging

Crucially, the back side of the weld joint (inside the pipe) must also be shielded with an inert gas (like Argon) during welding.

Control Heat Input

Minimize heat input during welding to reduce distortion and the risk of sensitization (carbide precipitation) in non-L grades.

Post-Weld Treatment:

- Cleaning: Remove all welding slag, heat tint (discoloration), and any contaminants from the weld area immediately after welding. Never use carbon steel brushes or grinding wheels.

- Passivation: This is a critical step after welding and cleaning. It restores the material’s complete corrosion resistance. Skipping or improperly performing passivation is a significant cause of premature pipe corrosion near welds.

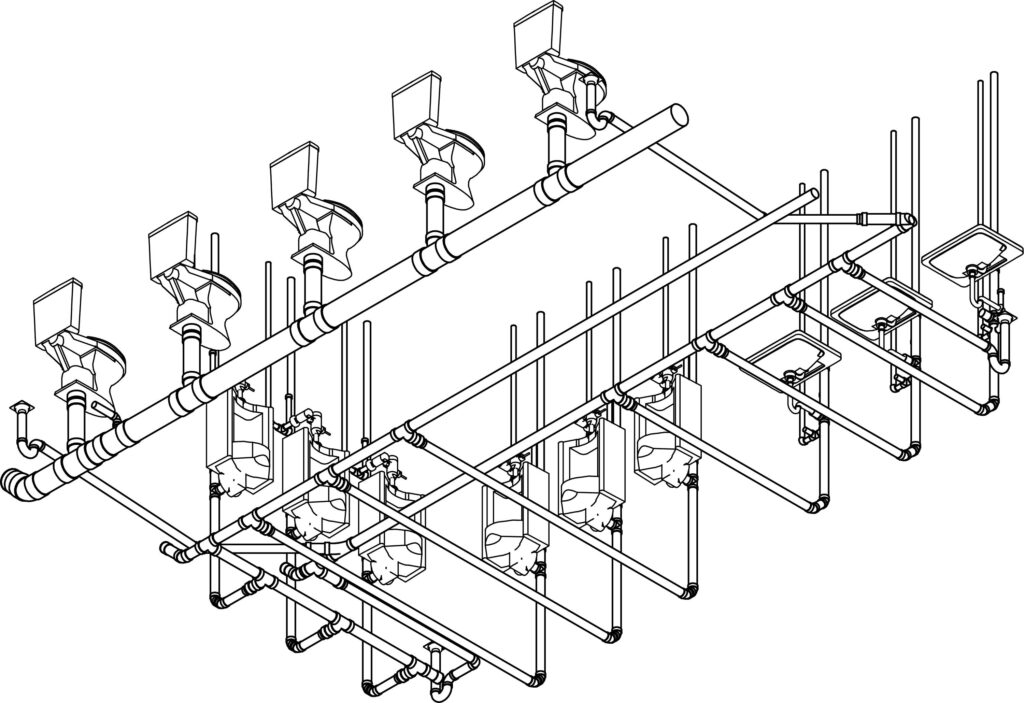

Designing and Installing Effective Pipe Supports

Properly designed and installed pipe supports are essential for managing the static and dynamic loads on the piping system, including the weight of the pipe, fluid, insulation, and thermal expansion stresses. Stainless steel pipe support problems can lead to catastrophic failure.

Importance of Support:

- Prevent excessive stress on pipes, fittings, and connected equipment (like pumps or vessels).

- Control thermal expansion and contraction movements.

- Prevent sagging or misalignment.

- Reduce vibration.

Types of Supports:

Range from simple clamps and hangers to complex spring supports and anchors. The type used depends on the system’s requirements (e.g., vertical vs. horizontal runs, thermal movement, vibration).

Preventing Support-Related Problems:

- Correct Spacing: Supports must be spaced according to engineering specifications to prevent sagging and excessive stress.

- Proper Installation: Supports must be securely attached to the structure and the pipe.

- Preventing Galvanic Corrosion: This is a significant risk at support points, especially when stainless steel pipes are in contact with dissimilar metals (like carbon steel supports).

- Allowing for Movement: Supports must allow for anticipated thermal expansion and contraction movement where required, using guides, slides, or spring supports as specified in the design.

- Preventing Wear: In vibrating systems, wear plates or liners may be needed at support points to avoid the support from abrading the pipe surface over time.

Preventing Corrosion in Stainless Steel Pipes

Corrosion is arguably the most insidious threat to stainless steel piping systems, leading to reduced lifespan and pipe leaks. While stainless steel is corrosion-resistant, it is not corrosion-proof. Understanding the causes of pipe corrosion and implementing prevention strategies is vital.

Understanding Corrosion Mechanisms:

- Pitting Corrosion: Localized attack causing small holes or pits on the surface. Often initiated by chloride ions disrupting the passive layer, especially in stagnant conditions or on rough surfaces.

- Crevice Corrosion: Similar to pitting but occurs within narrow gaps or crevices (under gaskets, in tight fittings, deposits on the surface) where oxygen is depleted, preventing repassivation.

- Stress Corrosion Cracking (SCC) occurs when a susceptible material is subjected to tensile stress in a specific corrosive environment (commonly chlorides or sulfides at elevated temperatures).

- Galvanic Corrosion: Occurs when two dissimilar metals are in electrical contact in an electrolyte (like water). The less noble metal (e.g., carbon steel) corrodes preferentially.

Common Causes of Pipe Corrosion:

- Chlorides: The most common culprit, especially in water-based systems, coastal environments, or processes involving salts.

- Stagnant Conditions: Lack of flow allows corrosive species (like chlorides) to concentrate and depletes oxygen needed for repassivation, promoting pitting and crevice corrosion.

- Poor Passivation: Inadequate or damaged passive layer.

- Contamination: Iron particles, carbon steel dust, welding slag, or chemical residues on the surface.

- Incorrect Material Selection: Using a grade not suited for the corrosive environment.

- Elevated Temperatures: Accelerate most corrosion mechanisms.

- Poor System Design: Creating dead legs or low-flow areas.

Prevention Strategies:

- Material Selection: Choose a stainless steel grade highly resistant to the specific corrosive agents and temperatures in your application (e.g., 316L or duplex grades for chloride-rich environments).

- Proper Passivation: Ensure all new stainless steel (especially after welding or mechanical work) is appropriately cleaned and passivated before service. Maintain passivation over time.

- Avoid Stagnant Areas: Design systems to minimize dead legs and ensure adequate flow.

- Cleaning and Maintenance: Regularly clean the external and internal surfaces of pipes to remove deposits, scales, or residues that can create crevices or harbor corrosive species.

Addressing the root cause (e.g., changing process conditions, upgrading material, improving cleaning) is crucial to prevent recurrence after repair.

Addressing and Preventing Leaks

Pipe leaks are a common symptom of underlying problems, be it poor installation, corrosion, vibration, or material defects. Preventing leaks starts with getting the basics right. Troubleshooting stainless steel pipe installation often involves identifying the source of a leak.

Common Leak Points:

- Fittings: Overtightened, undertightened, misaligned, or incorrect type.

- Welds: Porosity, cracks, lack of fusion, or intergranular corrosion in the HAZ.

- Flanges: Damaged gasket, improper bolt tightening sequence/torque, damaged flange face.

- Damaged Pipe Sections: Physical impact damage, severe localized corrosion (pitting leading to perforation).

Troubleshooting Leaks:

- Inspect the suspected leak area for signs of wetting, staining, or deposits.

- Use leak detection fluids or ultrasonic leak detectors for hard-to-find leaks.

- Pressure testing the system can help pinpoint leak locations.

- Examine the connection or weld closely for visible defects.

Preventing Leaks:

- Ensure all installation steps are followed meticulously, especially regarding fittings and flanges.

- Implement robust welding quality control to prevent weld defects.

- Address corrosion issues proactively before they lead to through-wall penetration.

- Ensure proper pipe support to prevent connection stress due to sagging or vibration.

- Use high-quality pipes and fittings from reputable suppliers.

- Regular inspection and maintenance can catch potential leak points before they fail.

Preventing Contamination

Maintaining the purity of the process fluid and the integrity of the stainless steel surface relies heavily on preventing contamination during fabrication, installation, and maintenance. Prevent stainless steel pipe contamination at every stage.

Sources of Contamination:

- Iron Particles/Dust: These particles come from grinding or cutting carbon steel nearby or using tools previously used on carbon steel.

- Carbon Steel Tools: Wire brushes, grinding wheels, or even wrenches used on carbon steel before touching stainless steel transfer iron particles.

- Shop Dust/Debris: General dirt, grease, paint, or other foreign materials.

- Inadequate Cleaning: Leaving welding slag, flux residues, or machining oils on the surface.

- Environmental: Exposure to corrosive atmospheres, dirt, or other contaminants during storage or installation.

Impact of Contamination:

- Initiation of pitting or crevice corrosion.

- Reduced product purity (critical in hygienic applications).

- Compromised system performance.

Prevention Methods:

- Dedicated Tools: Use tools (grinders, brushes, cutters, lifting gear) that are only used on stainless steel. Color-code or clearly label them.

- Clean Work Areas: If possible, fabricate and install stainless steel in areas segregated from carbon steel work. Keep work areas clean.

- Proper Cleaning: Thoroughly clean pipes and fittings after fabrication (cutting, welding) and installation. Use cleaners compatible with stainless steel.

- Passivation: Passivation removes free iron and promotes the passive layer, helping to clean up minor surface contamination.

- Protective Covers: Keep pipe ends capped and protect open sections of the system from dust and debris during installation pauses.

- Cleanliness During Maintenance: Ensure replacement components and tools used are clean and contaminant-free.

Implementing Robust Quality Control

Quality control (QC) is not a single step but an ongoing process integrated throughout fabrication, installation, and testing. It’s essential to verify that best practices are followed and detect potential problems before the system is put into service or escalates. Stainless steel pipe quality control is non-negotiable.

Importance of QC:

- Ensures adherence to specifications, codes, and standards.

- Identifies defects early when they are easiest and least expensive to fix.

- Provides documentation of system integrity.

- Helps prevent pipe failure and industrial piping issues.

Key Inspection Points:

- Material Verification: Confirm that the received materials match the specifications and have the correct mill certificates.

- Dimensional Checks: Verify pipe lengths, alignment, and fitting dimensions.

- Weld Inspection: Visual inspection of welds for obvious defects (undercut, porosity, cracking, heat tint, sugaring).

- Fitting and Flange Assembly Inspection: Visually check for correct alignment, gasketing, and bolt tightening pattern (torque verification may be required).

- Support Verification: Check support types, location, spacing, and isolation (for galvanic corrosion prevention).

- Cleanliness Check: Inspect internal and external surfaces for cleanliness and absence of contaminants before closing the system.

Testing Methods:

Pressure Testing (Hydrostatic or Pneumatic)

It is a fundamental QC step. The system is subjected to a pressure above its operating pressure to check for leaks or structural weaknesses. Hydrostatic testing (using water) is standard but requires careful draining and drying afterward, especially in systems sensitive to water quality or contamination.

Documentation

Maintain thorough records of material certificates, welding procedures (WPS) and welder qualifications (PQR), inspection reports (visual, NDT), and pressure test records. This documentation is invaluable for future maintenance, troubleshooting, or system modifications.

Maintenance and Long-Term Failure Prevention

Installation and QC are just the beginning. Regular maintenance is essential for the long-term health and reliability of industrial stainless steel piping systems. A comprehensive industrial stainless steel pipe maintenance guide should include routine inspections and preventative actions.

- Routine Inspection Schedules: Implement a scheduled program for inspecting the external surfaces of the piping system.

- Look for signs of corrosion (staining, pitting), leaks, damaged insulation, support issues (corrosion at supports, damaged isolation pads, loosened clamps), vibration, or signs of stress.

- The frequency of inspections depends on the service’s criticality, the environment’s corrosiveness, and operational history.

Cleaning and Passivation Maintenance:

Depending on the application, periodic cleaning of external or internal surfaces may be necessary to remove accumulated dirt, scale, or process residues that could lead to corrosion.

Conclusion

Ensuring the longevity and reliability of industrial piping systems, critical to many industries, demands expertise from design to maintenance. This guide emphasizes preventing common issues like improper installation, welding defects, and various forms of corrosion.

Operators can significantly reduce costly failures by implementing rigorous quality control measures, including thorough inspections and testing, as well as proper support and contamination prevention. Adhering to these best practices for installation and ongoing maintenance is a worthwhile investment, guaranteeing safer, more efficient, and durable operations.

Contact our experts for more information about stainless steel piping systems.

Know about us more

- The Importance of Corrosion Protection in Piping

This blog discusses corrosion prevention strategies, directly relevant to addressing common issues in stainless steel piping systems. - Comprehensive Maintenance Checklist for Industrial Piping Systems

This blog provides a detailed maintenance checklist, complementing the focus on preventing and troubleshooting problems in stainless steel piping. - NACE International (AMPP) – Corrosion Basics

AMPP offers authoritative resources on corrosion prevention, critical for addressing common issues in stainless steel piping systems. - Piping Technology & Products – Stainless Steel Piping Resources

This resource provides technical insights into stainless steel piping design and maintenance, supporting troubleshooting efforts.

Related Blog

Carbon Steel vs. Stainless Steel Piping: The Ultimate Guide for Industrial Facilities

This blog compares carbon steel and stainless steel piping, offering valuable context for understanding the unique challenges and solutions for stainless steel systems.

Need Help Preventing Piping Failures?

Our stainless steel piping experts can audit your system and recommend solutions to reduce leaks, corrosion, and downtime.