Mastering High Temperature Pipe Fittings: Your Step-by-Step Guide

Table of Contents

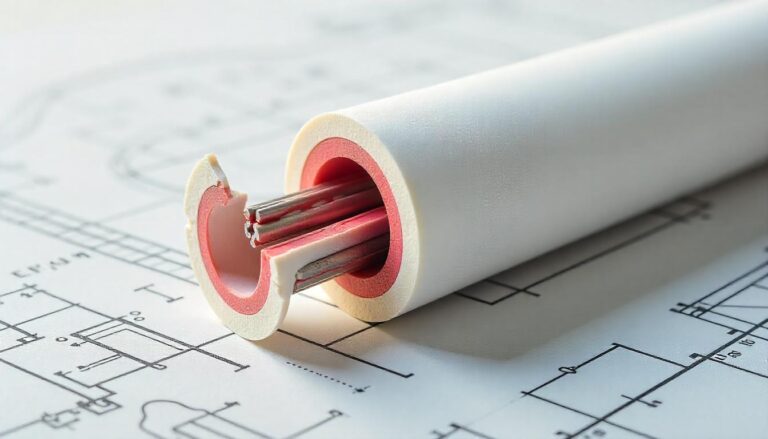

Designing, installing, and maintaining piping systems in extreme heat, common in power generation, chemical processing, and refining, is a critical challenge. The stakes are high: incorrect material selection, inadequate joining, or overlooked installation details for high-temperature pipe fittings can lead to catastrophic failures.

This guide provides a step-by-step roadmap to confidently select, install, and maintain these fittings, ensuring long-term integrity and compliance.

Step-by-Step Guide to High Temperature Pipe Fittings

Working with high-temperature pipe fittings demands a meticulous approach. Skipping steps or making assumptions can compromise the integrity of the entire system. Follow these steps to ensure your high-temperature piping system is designed, installed, and maintained for maximum safety, reliability, and longevity.

High-Temperature Service Conditions Assessment

Before selecting a single fitting, you must thoroughly understand the environment and demands of your piping system. This isn’t just about knowing the maximum temperature; it’s about a holistic view of the operating conditions.

What to do:

- Precisely determine the typical operating temperature range, including potential excursions (short periods during which the temperature exceeds normal limits).

- Identify the maximum system pressure and potential pressure surges that may occur.

- Analyze the substance being transported (fluid, gas, steam, chemicals). Is it corrosive? Does it contain abrasives? What is its pH level?

- Consider external factors, such as ambient temperature, insulation requirements, potential for external corrosion, and exposure to UV or harsh weather.

- Factor in cyclic loading: Will the system experience frequent startups, shutdowns, or fluctuations in temperature and pressure? This leads to thermal fatigue.

- Understand the system’s required lifespan. Is this a temporary setup or a critical infrastructure component designed to last decades?

Why it matters:

This detailed assessment is the absolute bedrock for every subsequent decision. It directly dictates the necessary material properties, pressure ratings, joining methods, and safety factors required for your pipe fittings for hot applications. An inadequate assessment is the fast track to premature high-temperature pipe fitting failures. Knowing the exact conditions helps you avoid both under-specifying (leading to failure) and over-specifying (leading to unnecessary costs).

Select the Right High-Temperature Pipe Fitting Materials

With your service conditions clearly defined, the next crucial step is choosing materials that can withstand those demands. This is the most critical decision when working with high-temperature pipe fittings. Different materials have dramatically different capabilities under heat and pressure.

What to do:

- Consult material property charts that list tensile strength, yield strength, creep strength, oxidation resistance, and corrosion resistance at various temperatures.

- Match the material’s temperature limits to your operating temperature range.

- Explore Chrome-Moly Alloys: Materials like P11, P22, and P91 are specifically designed for high-temperature power plant and refinery applications due to their creep resistance.

- Investigate Nickel Alloys: For extremely high temperatures, highly corrosive environments, or thermal cycling resistance, alloys such as Inconel, Hastelloy, or Monel may be necessary.

- Consider Non-Metallic Options (with extreme caution): While PVC, CPVC, and fiberglass-reinforced plastic (FRP) are suitable for some industrial applications (as noted in competitor analysis), their temperature limits are relatively low compared to those of metals.

Why it matters:

The material choice is the primary determinant of the fitting’s ability to maintain structural integrity, resist creep, oxidation, sulfidation, and corrosion under high heat and pressure. Using the wrong material will inevitably lead to premature failure, potentially jeopardizing safety, causing leaks, or necessitating costly repairs and downtime.

Choose the Appropriate Fitting Types and Joining Methods

Once the material is selected, you need to decide on the physical form of the fittings (e.g., elbows, tees, reducers) and, critically, how they will be joined together and to the pipe. The joining method has a profound impact on the integrity and reliability of high-temperature pipe fittings.

What to do:

- Select Fitting Types: Choose standard fitting shapes (elbows for direction changes, tees for branches, reducers for diameter changes, caps for ends, flanges for connections) made from the selected high-temperature material. Ensure they conform to dimensional standards (e.g., ASME B16.9 for Wrought Fittings, ASME B16.11 for Socket Weld/Threaded Fittings, ASME B16.5/B16.47 for Flanges).

- Consider Stress: Analyze how the chosen fitting types and joining methods will handle thermal expansion and contraction. Bends and expansion joints might be needed in the system design, but the fittings themselves must withstand the induced stresses.

- Factor in Maintenance: Threaded and flanged joints are more straightforward to disassemble for inspection or replacement than welded joints. This is a trade-off against potential leak paths.

Why it matters:

The strength and leak tightness of the joint are just as important as the material properties of the fitting itself. A weak joint in a high-temperature system is a guaranteed point of failure. Understanding the nuances of welded versus threaded high-temperature fittings and selecting the appropriate method based on pressure, temperature, fluid type, and maintenance needs is critical for the safe and reliable installation of high-temperature fittings.

Specify High-Temperature Gaskets and Sealants

For systems using flanged connections or threaded fittings, the gasket or sealant is the final barrier against leaks. In high-temperature applications, standard sealing materials often fail, making the selection of high-temperature gasket materials and sealants crucial.

What to do:

For Flanged Joints:

- Choose gasket materials rated for your maximum operating temperature and pressure. Common high-temperature gasket materials include:

- Graphite: Excellent temperature resistance (up to ~950°F or 510°C in oxidizing atmospheres, much higher in non-oxidizing). Available in sheets or spiral wound configurations. Often reinforced with metal inserts.

- Spiral Wound Gaskets: Feature a metal winding (often stainless steel or exotic alloys) and a filler material (like graphite or PTFE). The metal provides strength, and the filler includes sealing. Very common for high-pressure, high-temperature applications. Requires proper bolt load.

- Ring Type Joints (RTJs): Solid metal rings that fit into corresponding grooves in special flanges. Used in very high-pressure/temperature applications (e.g., oil and gas). Requires a significant bolt load.

- PTFE (Polytetrafluoroethylene): Useful for corrosive media but has a relatively low temperature limit (around 500°F or 260°C), making it unsuitable for many extreme high-temp applications.

For Threaded Joints:

- Select a thread sealant rated explicitly for high temperatures and pressures. Standard PTFE tape or pipe dope will melt or degrade.

- High-temperature paste sealants (often ceramic-based or containing metal particles) or high-temperature-rated anaerobic sealants might be suitable, depending on the exact conditions.

Why it matters:

The gasket or sealant is the weakest link if not correctly specified. Under high heat and pressure, standard materials will fail, leading to leaks, potential environmental hazards, energy loss, and safety risks. Using appropriate high-temperature gasket materials ensures a reliable seal that can withstand thermal expansion, pressure variations, and chemical attack at elevated temperatures.

Consider Coatings and Surface Treatments for Enhanced Performance

While the base material is key, applying appropriate coatings or surface treatments can further enhance the performance, lifespan, and efficiency of high-temperature pipe fittings.

What to do:

- Assess Environmental Factors: Is the external environment corrosive? Is thermal radiation a concern? Are there abrasive particles in the flow?

- Corrosion Protection: Apply high-temperature paints or coatings designed to protect against external corrosion, especially in harsh or coastal environments. Ensure the coating is rated for the operating temperature of the fitting’s external surface.

- Internal Protection: In highly corrosive or abrasive internal environments, specialized internal coatings (such as ceramic coatings or fusion-bonded epoxy, if the temperature permits) may be applied.

Why it matters:

Coatings can provide an extra layer of protection against degradation mechanisms accelerated by high temperatures, such as oxidation and corrosion. They can extend the service life of fittings, reduce maintenance requirements, and enhance energy efficiency in specific applications. Ignoring external protection can lead to premature failure from the outside in.

Install High-Temperature Pipe Fittings Correctly

Even the best materials and designs will fail if the installation is flawed. Installing high-temperature equipment requires precision, adherence to procedures, and often, specialized skills.

What to do:

- Surface Preparation: Ensure mating pipe ends or flange faces are clean, free of debris, grease, rust, or damage. Bevel pipe ends correctly for welding.

- Alignment: Achieve perfect alignment before joining. Misalignment induces stress w,hich is amplified at high temperatures and can lead to cracking or premature failure. Use proper pipe supports and temporary bracing.

- Support and Stress Relief: Ensure the piping system is adequately supported to prevent sagging or excessive stress on fittings, especially in systems that experience thermal expansion. Analyze thermal expansion and install expansion loops or joints as required by design and pipe fitting standards for high temperatures.

- Pressure Testing: After installation, the system must be pressure tested (hydrostatically or pneumatically, following safety protocols) to verify joint integrity before commissioning.

- Documentation: Keep detailed records of installation procedures, welding logs, NDT results, bolt torque reports, and pressure test certificates.

Why it matters:

Improper installation introduces stresses, creates potential leak paths, and weakens the fittings, significantly increasing the risk of high-temperature spipe fitting failures. Correct installation ensures the system performs as designed, safely contains the high-temperature fluid, and complies with critical safety standards. Precision during the installation of high-temperature fittings is non-negotiable.

Implement Robust Monitoring and Maintenance Strategies

Even a perfectly designed and installed high-temperature piping system requires ongoing attention. High temperatures accelerate degradation, making proactive monitoring and maintenance essential to prevent unexpected high-temperature pipe fitting failures.

What to do:

- Regular Visual Inspections: Schedule routine visual checks for signs of leakage, corrosion, insulation damage, bolt looseness (especially on flanged joints), cracking, or deformation. Pay close attention to areas around fittings.

- Bolt Retorquing: For flanged joints operating at high temperatures or experiencing thermal cycling, periodic bolt retorquing might be necessary, following strict safety procedures and guidelines.

- Consider Smart Monitoring: Explore the use of innovative pipe fittings for high-temperature solutions.

- Integrated Sensors: Monitoring temperature, pressure, vibration, or even acoustic emissions (for detecting early signs of leaks or cracking).

- Corrosion Monitoring Sensors: Detecting material loss over time.

- Wireless Connectivity: Transmitting data wirelessly for remote monitoring and predictive maintenance analytics (pipe IoT applications). These provide real-time data on the health of fittings.

- Failure Analysis: If a failure occurs, conduct a thorough investigation to determine the root cause (e.g., material issue, installation error, operating conditions, thermal fatigue) and prevent its recurrence. Understanding common high-temperature pipe fitting failures (like creep rupture, stress corrosion cracking, oxidation, thermal fatigue) is key to effective maintenance.

Why it matters:

High temperatures and thermal cycling constantly stress fittings and joints. Degradation mechanisms, such as creep, oxidation, and fatigue, are accelerated. Proactive monitoring allows for early detection of potential issues before they escalate into dangerous or costly failures. Implementing a robust maintenance plan extends the system’s life and ensures continued safe operation.

Conclusion

Navigating the complexities of high-temperature pipe fittings is undoubtedly challenging, but it’s an essential skill for ensuring the safety, efficiency, and longevity of critical industrial systems. By understanding the unique demands of hot applications and following a structured approach, you can make informed decisions that prevent costly failures and safeguard your operations.

Investing time in proper planning, material selection, precise installation, and diligent maintenance pays dividends by preventing catastrophic high-temperature pipe fitting failures, minimizing downtime, and ensuring regulatory compliance. You’ve got this, and your facility’s safety depends on it.

Need expert assistance or specialized high-temperature pipe fittings? Discover SRJ Piping India’s solutions next.

Selecting the right pipe fittings for high-temperature environments is critical for operational safety and longevity. For deeper insights, explore our guide on Carbon Steel vs. Stainless Steel Piping to compare material performance under thermal stress, and review our Comprehensive Maintenance Checklist to prevent heat-related failures. Externally, Spalloys’ analysis of Stainless Steel Fittings for High Temperatures offers technical benchmarks, while McWane Ductile’s breakdown of Temperature Impact on Material Selection provides essential design considerations. Always prioritize certified materials and proactive inspections to mitigate thermal degradation risks.

Need Support with High-Temperature Pipe Fittings?

SRJ Piping India offers expert assistance in selecting, installing, and maintaining fittings that withstand extreme heat, pressure, and corrosion—ensuring safe and reliable operations in critical environments.